By John Hughes

In the early 1970’s Dick Catri got wind of a new space age fabric called Kevlar, that was lighter and more durable than the conventional fiberglass cloth commonly used in surfboard construction. It had been incorporated into commercial use- notably for tire belts- but was not available to the public. Dick contacted the manufacturer, DuPont Chemicals, and they put him in touch with Stephanie Kwolek- the the chemist who had invented the material- who gave him some basic information on working with the product. He was able to purchase a few yards of the material and took it back to his factory on Tomohawk Drive to try it out.

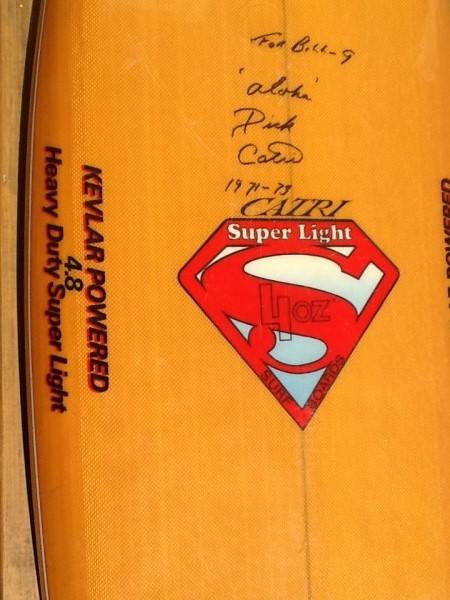

Although the Kevlar fabric produced a lighter and stiffer surfboard, it was notoriously difficult to work with. The heavier 4.8 oz. cloth could only be cut with special serrated scissors. The stiffness of the fabric would not allow conventional lapping techniques so the laminators would hang fishing weights to the fabric to get it to drape properly. They then they cut the lap with razor blades which had to be replaced every four inches. After the Kevlar had been laid up, the board was final glassed with conventional 6 oz. fiberglass cloth. Most of the lamination was done by Bob Keller who was paid $100 where the pay for a conventional surfboard was $30. Additionally Kevlar cloth cost $10 a yard when the price of fiberglass cloth was only $3 a yard.

Naturally, the Kevlar boards were considerably more expensive and relatively few were manufactured. Dick estimates that less than 100 were made, most of them in the early to mid 1970’s. Many of them were shaped by George Robinson. The longboard pictured is made with a Kevlar/carbon fiber weave and was most likely built in the mid-1980’s. There was also an 8’4″ Kevlar/carbon fiber board shaped off of a Brewer template that was made for David Speir. It was famously featured with Dick in a Hang Ten advertisement that was placed in several surf publications.

I remember when those were made and it was said that you could throw them out of a car window at 60 mph and there would be no damage, my first board was a Catri.

I have a 6’6″ Catri Superman board,, single fin, if anyone is interested in it,,,

Can you send photos?

Hi my friend o Eduardo Abarca from Chile

I have a catri superligth hand shape by geroge Robinsón I have this board like 15 years.

In my travels I by this board in bad shape but this board is the best.

This is my number if you wont this board to the musseum .

My regrats

EDUARDO Abarca

EDUARDO ABARCA

+56995313593

EA******@***IL.COM